Do you hear unusual noises while driving? The quality of the pinion on your truck can be compromised. In this scenario, knowing how to replace pinion bearing on chevy truck can be helpful.

Materials Needed to Repair a Ring gear bearing for Chevy Truck

When working from home, avoiding scratching or breaking the drive shaft is critical. It must be gently removed. It would also help if you possessed the necessary equipment.

When changing the pinion bearing, you’ll need important equipment and specialized tools.

- A press

- Old suppressor cinches

- Pry bar

- Hammer

- Force wrench (in strange conditions)

- Wrench

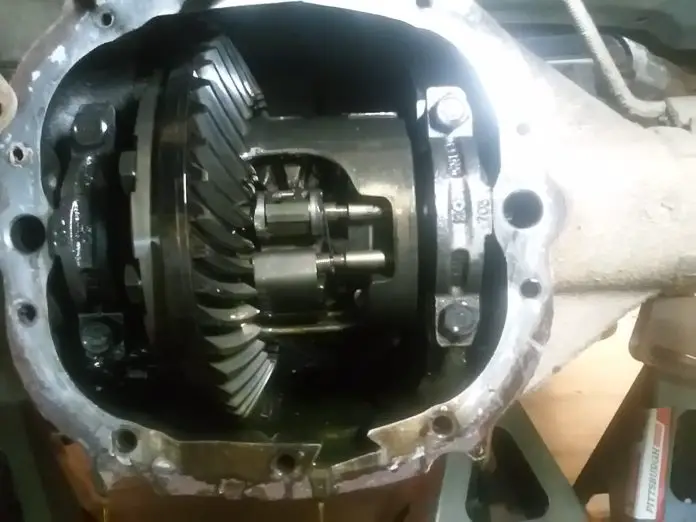

How to Replace Pinion Bearing on a Chevy Truck?

Certain technical measures are required to replace the gear bearing on a Chevy Truck. You may simply do it at home since you’re not custom-made to mechanical work.

The instructions for replacing your Chevy pickup are as follows.

Disconnect the driving shaft.

To remove the nuts and bolts, use the pliers with a screwdriver. Four screws are on their path. Once the screws are excessively tight, loosen them using a powered screwdriver and some lubricant. Lower the shaft of transmission when one of the edges is unfastened.

Remove the differential fluid and drain it.

Differential fluid has started to leak. If you don’t use the bucket, it will end up in various locations. This is a perfect time to replace rapid flow once it hasn’t been replaced in a long time. Otherwise, the accumulated liquid can be reinserted.

Take out Wheel

When the gearbox is installed and removed, it will be much easier to remove the pinion. The differential must also be removed by removing the bolts. The pinion is held in place by certain seals. They should be released and deleted. You may need a claw hammer to unlock the coal-based power circuit.

Get the races started.

The pinion is known for its races. These races maintain the pinion’s position and aid in its correct operation. Remove the pinion ring using a mallet and a rod. Take away three races.

Replace the bearing.

Remove the pinion’s other nuts and bolts. Remove the bearing by unscrewing the bearing seal.

You can achieve this by leveraging a rubber hammer. For this, use the press and the damper clamp. If it becomes stumped, take it to a professional. Who has the necessary equipment to free it? Remove the archaic sign and replace it with a new one. The washing machine may be replaced or reused. Double-check that all is secure before tightening.

Install the Pinion Gear again.

Change the spindle. Once the bearing has been replaced, ensure all the screws are secure.

It is not recommended to add new races since they may become corrupted. While driving, a minor scrape generates a noise.

Place the gap, including the drive shaft, in their proper locations. Make care you place each element in its designated spot at these locations.

You will have difficulty driving otherwise. And even little errors can have serious consequences.

Frequently Asked Questions

What amount does it cost to supplant a pinion bearing?

Replacing a pinion bearing costs on average $239-286. The parts are estimated at $66-$68, while the labor cost would be about $173-$218.

What are the signs that you’re using the wrong rear pinion bearing?

A whistling deceleration noise may indicate a bad or loose pinion bearing. Howling during acceleration can be the same problem. Only at speeds above 20 mph a rumble or whine can be a sign of worn bearing bearings on the carrier. The sound may change when cornering.

How do you recognize a bad pinion bearing?

Worn gears, pinions, and faulty gear settings are the most common causes of howling or howling during acceleration in a limited or wide speed range. Rumbling or grunting at speeds above 20 mph can be caused by worn bearings on the carrier. The sound may change as it spins.

What makes a pinion bearing?

Pinion bearings are intended to decrease friction and boost efficiency in the direction of the desired motion. For drive differentials, the pinion bearings help the smoothest gears in the differential run smoothly.

What happens if the preload on the pinion bearing is adjusted inaccurately?

The pinion spins at the same speed as the driving shaft and can simulate vibrations caused by that speed. Improper pinion bearing preload can cause what looks to be a pinion seal leak, yet the seal is fine, and the pinion spins vertically, horizontally, or diagonally.

How important is the pinion preload?

The bearing preload can be adjusted slightly to maintain adequate blade contact between the pinion and ring gear. This reduces gear wear and extends the life of both gears’ teeth. When gear wear is minimized, impurities in the shaft system are reduced.

What is a pinion bearing’s pressure?

Pinion preload is the thrust acting on the pinion tapered roller bearings. The collapsible spacer is used to obtain a certain amount of pressure or preload. This spacer is located between the bearings. Turning the pinion nut crushes the spacer to achieve the prescribed preload.

How long do pinion bearings last?

Now, if you look for a time frame, it could be ten days or ten years. Low damage bearings can last ten years, while extreme damage does not last ten days.

Conclusion

You could save a lot of funds by understanding the time and season to repair a Chevy pinion bearing. This is, however, an extremely difficult and sensitive process.

As a result, before you begin changing the bearings, ensure you understand the Bearings components for the gearbox and shaft. You can accomplish it quickly after you are familiar with the pieces and technique.

Be sure that there is an adequate period to finish the operation. Instead, you’ll end up with a half-finished project.