A ballast Ignitor is a device used mainly in electricity generation plants. It is an electronic component whose primary role is to ignite the gas used in these plants. Ignition of the gas depends on how powerful the ballast is. If it is too weak, the gas will not ignite, and there will be no electricity production. Therefore, it is necessary to test the ballast ignitor to ensure that it works well.

How to Test Ballast Ignitor

Procedure to Follow When Testing Ballast Ignitor

Here is the strategy you should follow when testing ballast ignitors. First, wait until the pilot lights, and then turn on the power. Next, check if the LED is on. If so, the ignitor should be working correctly. If the LED is not on, check the ballast energy source and breaker box.

If the energy source and TV are working correctly, check the ignitor for blown fuses and broken wires if the ignitor is working correctly. There may be a faulty control board. Upgrade your equipment to shift from an analogue to a digital system to improve operational efficiency and save money.

How to Test Ballast Ignitor through Continuity Test?

On a ballast ignitor, use the continuity test to see if the ignitor is functioning correctly. Check that the ignitor is not shorted or open and that it does not energize when it should not be or not energized when it should be. If a multimeter is not available, test the ignitor with a jumper wire. Note that this test performs with the ignitor in the circuit. And thus will cause a short if the ignitor is open.

How to Test Ballast Ignitor through Ohms Test?

Follow the steps to test the ballast ignitor through the ohms test:

- Remove the wire off the ballast coil.

- Check the resistance on the ballast coil through ohms.

- Revolve the ignition and review the ohms.

- If the ohms are more than 5000, you can find the ballast coil is OK.

- If the ohms are less than 5000, then the ballast coil is shorted or open, and you need to change the ballast coil.

Test Ballast Ignitor through Diode Test:

The diode test utilizes for testing the ballast ignitor. Instead of a diode, we use a test light for the other ignitors. The reason for this is simple. When trying ballast ignitors, you can’t remove the ignitor from the circuit, so you can’t check for voltage across the ignitor’s leads (a diode test requires you to find the hot and load wires and check to see if a voltage is present on both of those wires).

You can’t just check for a hot wire with ballast ignitors because there is no hot wire. A diode test would require additional wiring to lead to the ballast ignitor. Once the ignitor installs, you can’t see the back of the ignitor, so it’s impossible to know which wire is which. You can’t see the back of the ignitor because it’s hidden inside the ballast. So instead, we check for power at the leads of the ignitor with a test light.

Steps To Check The Ballast Ignitor Through A Voltmeter?

Using electronic ballast, you can use a voltmeter to test the ignitor:

- Remove the ignitor from the lamp.

- The black test leads to the black wire in the lamp and the other lead to the white wire.

- Place the red test lead on the lamp’s transformer frame.

- The ignitor is working when you can read 3 volts DC between the black lead and the ignitor frame. And the ignitor is terrible if you can’t read any DC voltage.

- If you are using magnetic ballast, you can’t use a voltmeter to test the ballast because electronic ignitors do not utilize in magnetic ballast.

- The only way to test magnetic ballast is to remove a lamp and test the ignitor with a voltmeter.

How to Use a Power Supply to Test the Ballast Ignitor?

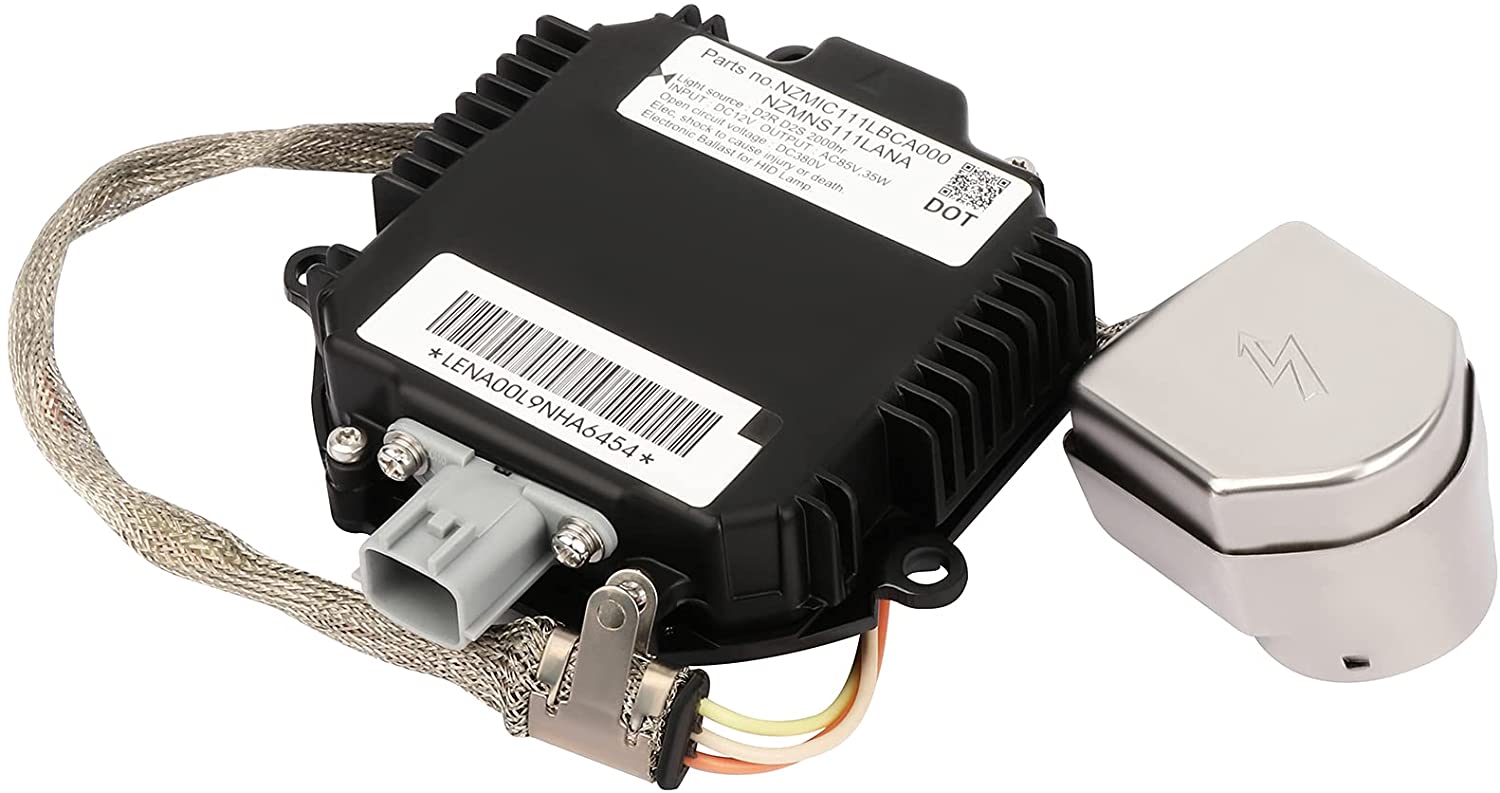

The ballast ignitor is what initiates the lighting of the filament. The ballast ignitor is placed inside the ballast and connected to an AC power supply. There are two ballast types, magnetic and electronic, and one needs to use ballast that matches the kind of ignitor.

For example, an ignitor connected to magnetic ballast must connect to magnetic ballast. One uses a power supply to test the ignitor. Some ballasts and ignitors have a built-in power supply to test the ignitor. In this case, the power supply only needs to have the same power frequency and current rating as the ballast.

How to Check the Ballast Ignitor through the Ballast Tester?

It is possible to test the ignitor of ballast with the help of a ballast tester, but it will not always be the most convenient or accurate of tests. Ballast ignitors use to ignite gas-discharge (neon or other types) lamps. They are an electric ignition system that uses a high-voltage arc produced between two electrodes to ignite a gas discharge lamp. The ignitor is not always a separate component from the ballast, but sometimes it can be.

The tester will sometimes be able to check the ignitor, but it will require you to unsolder one or both leads from the ignitor because they need to short together while the ignitor energizes. The problem is with the ignitor leads, not the ignitor. The ballast tester is set to a very high voltage and will not have a low enough current flow to check the ignitor.

Frequently Asked Questions

What Is The Easy Way To Test The Ballast Ignitor?

- Change the voltage and check whether it can ignite. If yes, the ballast is OK.

- When the ballast turns on, there should be an arc between the ignitor and the bulbs.

How Do You Test An HPS Ignitor?

- I take a 12V battery and short the leads of the ignitor until it lights.

- I ground the leads and then applied a variable DC power supply to test its current.

- Measure the resistance between the ignitor leads.

How Can You Test A Metal Halide Ignitor?

- I would use a voltmeter to test for resistance

- I would unscrew the ignitor to see if it has a resistor inside

How Can You Test An Igniter With A Multimeter?

Place the red probe into the L1 port and black into the L2 port, then turn on the ignition

Conclusion

In conclusion, a ballast ignitor is a device that provides the power needed to start a gas furnace. It is essential to have all of the components checked and working to prevent an interruption in heating. First, to try a ballast ignitor, detach it from the energy reserve before testing. Next, measure its voltage output using a voltmeter.

James Carter is an automotive blogger, reviewer, and technology enthusiast based in the USA. With a deep passion for cars and years of experience following the automotive industry, James focuses on delivering honest, well-researched content that helps readers make smarter decisions.